Bioenergy

-

From Biomass to Advanced Biofuels and Bioproducts

Innovation stemming from advanced biotechnology-based research is key to accelerating needed improvements in the sustainable production of lignocellulosic biomass, its deconstruction into sugars and lignin, and conversion.

-

Comparing Potential Biomass- and Petroleum-Derived Products

Today, petroleum-derived products are found in virtually all facets of human life, including transportation, recreation, communications, health, housing, food safety and supply, and textiles. Lignocellulosic biomass has the potential to (1) replace petroleum and natural gas as the raw material for producing these products and (2) provide new and improved properties that could enable new products and applications. As commercial-scale production of ethanol derived from lignocellulose is coming online, synthetic biology and metabolic engineering can be applied to convert lignocellulosic biomass into any number of chemical intermediates, building blocks, and final products. By no means exhaustive, this figure represents some examples of chemical intermediates and building blocks that could be gleaned from lignocellulosic biomass to make the same products currently derived from fossil feedstocks.

-

Feedstock Optimization with ORNL Staff Scientist

Udaya Kalluri, a senior staff scientist at Oak Ridge National Laboratory, examines naturally varying greenhouse-grown poplar genotypes. Greenhouse and field trials enable researchers to measure important phenotypes of growth, composition, and sustainability.

-

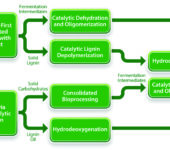

Feedstocks to Biofuels

CBI’s process follows either one of two conversion paths from sustainable, process-advantaged feedstocks to sustainable aviation fuels (SAFs). In one path (top), carbon-efficient conversion occurs via consolidated bioprocessing (CBP) with cotreatment in which carbohydrates are converted first. Fermentation intermediates are then catalytically upgraded, and lignin-enriched residuals are deconstructed and deoxygenated into SAF blendstocks. In an alternate path (bottom), carbon-efficient conversion occurs via a reductive catalytic fractionation (RCF) process in which lignin in whole biomass is converted to RCF oil that is then deoxygenated to SAF blendstocks. Carbohydrate-enriched residuals are subsequently deconstructed and converted to fermentation intermediates via CBP and then catalytically upgraded into SAF blendstocks.

-

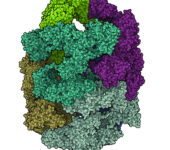

Fatty Acid Synthase

Fatty acids mimic some of the high–energy density properties that characterize hydrocarbon components of petroleum-derived fuels. Pictured is a computational model of the crystal structure of a fatty acid synthase. Joint Bioenergy Institute research has facilitated the discovery of a variety of enzymes and metabolic pathways that enable the biochemical conversion of fatty acids to a range of industrially relevant compounds.

-

Improved Biomass Conversion

GLBRC researcher Trey Sato monitors yeast cultures in his lab at the University of Wisconsin–Madison. Sato and colleagues have engineered yeast to feast on a previously unpalatable sugar, potentially improving the microorganism’s ability to convert sugars to specialty biofuels.

-

High-Yielding Sorghum

Sorghum, a key bioenergy and bioproduct feedstock, is harvested at the 320-acre Illinois Energy Farm.

-

Hyper-Spectral Imaging of Poplar Indicates Biogeochemistry

The Advanced Plant Phenotyping Laboratory will gather multiple plant phenotypes at high throughput generating terabytes of data. Hyper-spectral images indicate leaf water, nitrogen, and biochemistry.

-

GLBRC Research in the Laboratory

Digestible Lignin. GLBRC researcher Rebecca Smith focuses on how to make lignin more digestible. Lignin is the notorious hard-to-process “glue” that lends plant tissues their structure and sturdiness.

-

Miscanthus Field in Alabama

Mohammad Belaffif, a CABBI postdoc at the HudsonAlpha Institute for Biotechnology in Huntsville, Ala., walks in a Miscanthus field.